TM Covers

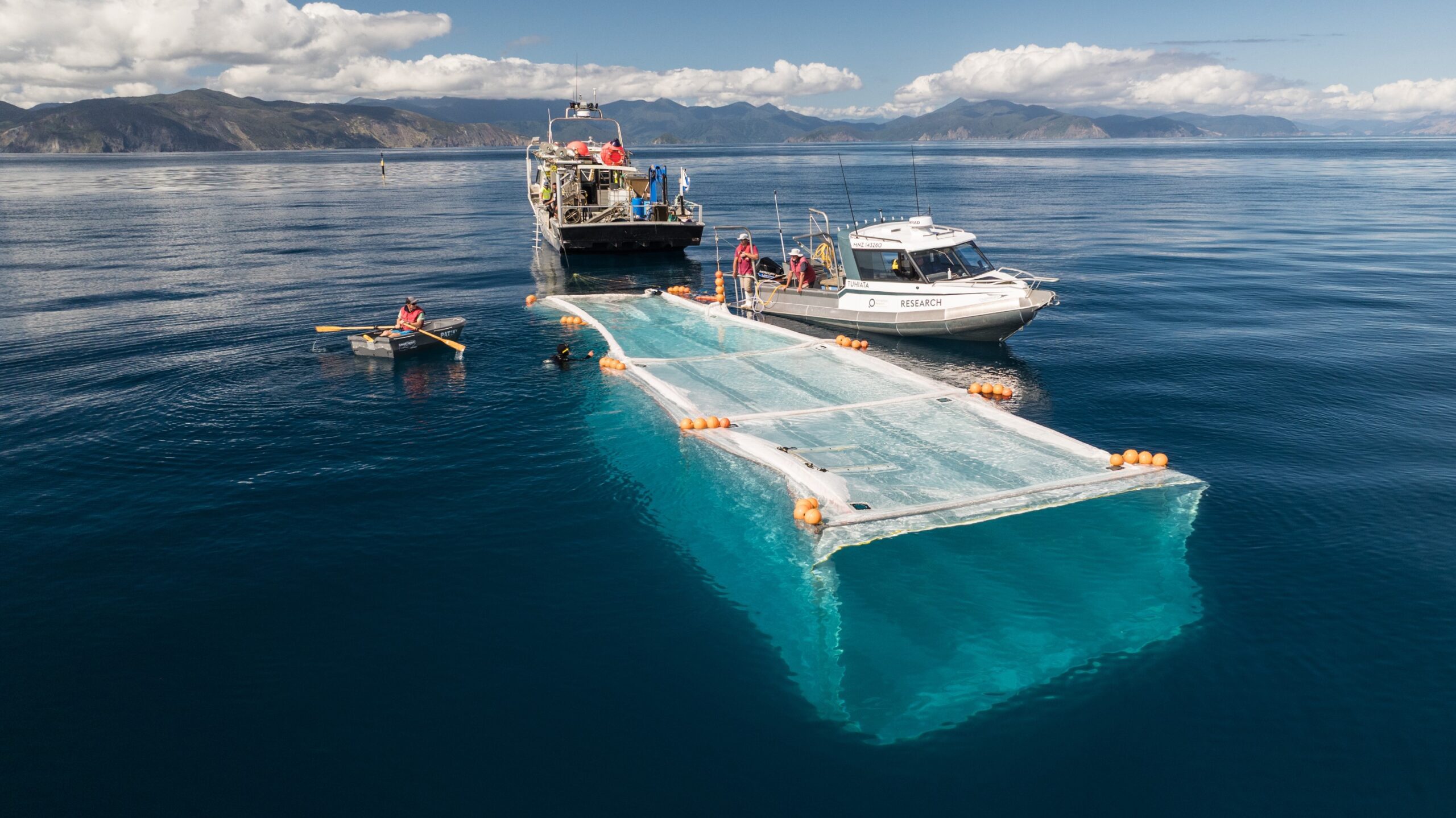

Project name: Mobile Fish Farm

Material used: HDMPE

Designer Company: Plant & Food Research & TM Covers

Project name: Mobile Fish Farm

Material used: HDMPE

Designer Company: Plant & Food Research & TM Covers

What did the client request?

This project was the culmination of months of collaboration with our client and followed a series of design meetings, sample trials and fabrication of a smaller prototype before this project was commenced. Consideration of factors including that the product would be deployed in the open sea and operational features needed to be able to be used by glove wearing divers, so planning and thoughtful design was critical.

This project has been recently reported in nationwide media as a groundbreaking programme for the raising of snapper off the South Island coast. It is an innovative use of fabric to create a low impact and environmentally friendly product to aid food production into the future.

Challenges we faced were working the a fabric with largely unknown properties that required many trials for optimal fabrication. Trials were required to get the fabric to weld well and the fabric also caused our scissors to go blunt! The size of the cover meant physical manipulation was difficult exceeding our bench size meaning the fabric had to be manoeuvred during fabrication so keeping weld and sewing lines straight was hard.

Production had commenced when our clients changed the design to include and accommodate more hoses and sensors.

What makes this project unique?

This project was the culmination of months of collaboration with our client and followed a series of design meetings, sample trials and fabrication of a smaller prototype before this project was commenced. Consideration of factors including that the product would be deployed in the open sea and operational features needed to be able to be used by glove wearing divers, so planning and thoughtful design was critical.

This project has been recently reported in nationwide media as a groundbreaking programme for the raising of snapper off the South Island coast. It is an innovative use of fabric to create a low impact and environmentally friendly product to aid food production into the future.

Challenges we faced were working the a fabric with largely unknown properties that required many trials for optimal fabrication. Trials were required to get the fabric to weld well and the fabric also caused our scissors to go blunt! The size of the cover meant physical manipulation was difficult exceeding our bench size meaning the fabric had to be manoeuvred during fabrication so keeping weld and sewing lines straight was hard.

Production had commenced when our clients changed the design to include and accommodate more hoses and sensors.